We Mean Business

Industry Elite Services is a full-service roofing company from residential services to commercial. We are dedicated to making you, the business owner, happy. We have a healthy client referral program that allows us to meet and impress new clients on a regular basis. Hopefully our way of doing business will appeal to you, and we’ll be able to add you to our ever growing list of satisfied clients!

We look forward to listening to your concerns and providing the exceptional service you and your family deserve. We listen to all our clients’ feedback and then use it to improve how we serve you and future clients. It is our goal to be the best roofing company we can be, no matter where we take our services. We hope you will consider Industry Elite for your next residential or commercial service! Please contact us with any of your questions.

Types of Commercial Roofing

TPO (Thermoplastic Polyolefin)

Thermoplastic polyolefin (TPO) is leading the trend in white, reflective, energy-efficient, single-ply roofing systems—and is the fastest-growing commercial roofing membrane on the market today. TPO has garnered broad industry acceptance for its many installation and performance advantages, including its ability to be heat-welded, creating a monolithic roof while providing strength and durability. Its white reflective membrane also meets the criteria of LEED®, ENERGY STAR® and other environmental programs. TPO & PVC are one of the top flat roof options due to its ease of installation and its resistance to water ponding. The seams in the TPO/PVC system are “Hot Air” welded using a computerized robot in most case creating less maintenance and/or repair visits. TPO sheets contain colorant, flame retardants, UV absorbers and other proprietary substances to achieve desired physical properties.

Best for: ENERGY EFFICIENCY • HEAT REFLECTION • PERFORMANCE

PVC (Polyvinyl Chloride)

PVC is a flexible, thermoplastic membrane manufactured using ultraviolet-resistant polyvinyl chloride. The membranes are produced in numerous colors, though gray and white are the most common.TPO & PVC are one of the top flat roof options due to its ease of installation and its resistance to water ponding. The seams in the TPO/PVC system are “Hot Air” welded using a computerized robot in most case creating less maintenance and/or repair visits.

Best for: DURABILITY • HEAT REFLECTION • WITHSTANDING TOUGH WEATHER + CHEMICALS

EPDM (Ethylene Propylene Diene Terpolymer)

EPDM has the longest proven performance record of all single-ply membranes. Its high-performance synthetic rubber compound provides exceptional weathering in climates across the globe. The material is easy to install and can be either fully adhered, mechanically attached or ballasted. The EPDM system seals are bonded with adhesives and this makes the seams vulnerable over long periods of time. The sealing system/process may lead to maintenance and/or repair issues. Over time, EPDM Rubber Roofs tend to shrink and pull back.

The membranes commonly are black, but white is available.PDM roof membranes can be installed fully adhered, mechanically attached (using batten bars) or ballasted. Most EPDM membranes do not receive surfacings.

Best for: DURABILITY • FLEXIBILITY • UV RESISTANCE

SBS (Styrene Butadiene Styrene)

A standard modified bitumen roof system has a base sheet or ply then a waterproofing sheet similar to single-ply. Modified bitumen’s use a traditional waterproofing medium — asphalt — modified with atactic polypropylene (APP) or styrene butadiene styrene (SBS).

SBS modifies the asphalt by forming a polymer network within the bitumen. SBS gives the bitumen rubber-like characteristics and improved resistance to aging and weathering. Most SBS modified bitumen sheets are set in hot mopping asphalt, torch-applied, or adhered with cold-process adhesives. SBS modified bitumen sheets that do not have factory applied granule or foil surfacing need some form of field-applied ultraviolet protective coating.

Best for: COLD ENVIRONMENTS • DURABILITY

APP (Atactic Polypropylene)

A standard modified bitumen roof system has a base sheet or ply then a waterproofing sheet similar to single-ply. Modified bitumen’s use a traditional waterproofing medium — asphalt — modified with atactic polypropylene (APP) or styrene butadiene styrene (SBS).

APP (Atactic Polypropylene) is a thermoplastic polymer, which forms a uniform matrix within the asphalt. This enhances the bitumen’s performance by increasing its UV resistance, increasing its flexibility at low temperatures, and improving its flow resistance at high temperatures. APP modified bitumen sheets are applied using a propane-fueled torch. Applicators use the heat to soften the modified bitumen on the underside of the sheet. The sheet’s bottom surface becomes a molten adhesive, which flows upon the substrate and then cools to form a waterproof adhesive bond. Some APP sheets can be applied with cold-process adhesive.

Best for: COLD + HOT ENVIRONMENTS • DURABILITY • UV RESISTANCE

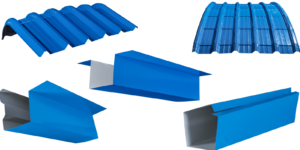

Commercial Roofing Accessories

Gravel Stop

A gravel stop is a metal flashing shape attached to roof structure to protect the roof edge against water penetration and to contain a built-up roof and prevent its gravel surface from falling over the roof edge. They are used where flat roofs end to provide a weathertight transition between roof and wall.

Where possible, gravel stops are installed over cant strips or raised curbs. When installed on a concrete or a steel deck, a wood nailer is required. Gravel stops are, in general, about 3/4″ high and formed from copper sheet 8 to 10 feet long. The copper apron extends 4″ onto the roof deck. The sheets are fastened to the roof deck by nails spaced 3″ O.C. The ends are lapped 3″ minimum. The lapped joint on the horizontal flange is set in mastic or elastic sealant. On vertical surfaces, the lapped sheets are held together by a clevis seam. On sloped surfaces, the clevis seam is filled with sealant before assembly.

Provides a professional appearance while securing roofing membrane

Drip Edge

A drip edge is a non-staining and non-corroding material applied on a roof’s edge to give water the ability to filter out of the roof system. In other words, it is the metal flashing located at the edge of a roof. A drip edge is installed with an intended tilt, which is specifically meant to direct water away from a roof while assuring the foundation of your roof is not exhausted prematurely by holes or fissures.

Drip edges not only act to preserve the appearance of your roof, but they help shield your property from potential damages.

Gutter Apron

A Gutter Apron, also known as L- Metal, is installed above your roof decking and sits over the edge of your gutter. Gutter aprons are installed right under your shingles as well. This directs water straight into the gutter system and also protects your roof line from excess moisture.

Inexpensive to install and can save you a lot of money in future repairs

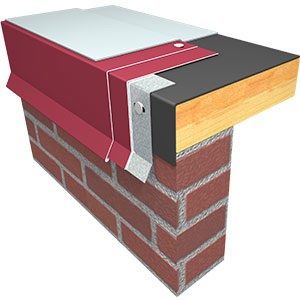

Coping Cap

The coping cap is the protective cap or cover on a wall, typically slanted or curved to shed water, protecting the wall from water infiltration from above.

This unique type of cap is designed to cover the top of parapet walls. Many buildings have flat roofs in certain areas specifically for air condoning units and etc. At the edge of these roofs, parapet walls are commonly found, and are vulnerable to leaks if not flashed correctly.

Stops water infiltration into walls that can lead to water damage

Additional Metal Accessories

At Industry Elite Services, we are here to help you from start to finish. We equip our team to service any part of your roof. Industry Elite Services commits to finding the best fit your roof. Our staff will work with you to make sure you have the best solution for you specific roof.

We work for and with you